Cutting Capabilities

Laser Cutting

Our 4000-Watt lasers can quickly and accurately cut almost any type of material with a smooth, dross-free edge that requires little or no clean up. C02 laser-cutting technology has become the most cost-effective cutting method for many applications. For both short and long runs, lasers provide many real advantages. We use Mitsubishi Laser Cutters with a positioning tolerance of .00039 and repeatability of .00020. Our Laser Cutters are equipped with 5' x 10' and 6' x 12' tables which can accommodate large assemblies or produce multiple assemblies from a single sheet of raw material. With three fully operational laser cutters, we offer quick turn-a-rounds while ensuring the highest quality parts for our customers.

Our 4000-Watt lasers can quickly and accurately cut almost any type of material with a smooth, dross-free edge that requires little or no clean up. C02 laser-cutting technology has become the most cost-effective cutting method for many applications. For both short and long runs, lasers provide many real advantages. We use Mitsubishi Laser Cutters with a positioning tolerance of .00039 and repeatability of .00020. Our Laser Cutters are equipped with 5' x 10' and 6' x 12' tables which can accommodate large assemblies or produce multiple assemblies from a single sheet of raw material. With three fully operational laser cutters, we offer quick turn-a-rounds while ensuring the highest quality parts for our customers.Waterjet Cutting

Waterjet Cutting Technology is a computerized cold-cutting technology that can cut most materials into any two-dimensional shape. Our system will precision cut materials such as carbon steel, stainless steel, aluminum, titanium, stone, glass and plastic up to six inches thick at a tolerance of plus or minus .005 or better. We can create parts, signs, art pieces, architectural applications; in fact, anything that can be drawn on a computer can be cut using our waterjet cutting system on the 6' x 12' table.

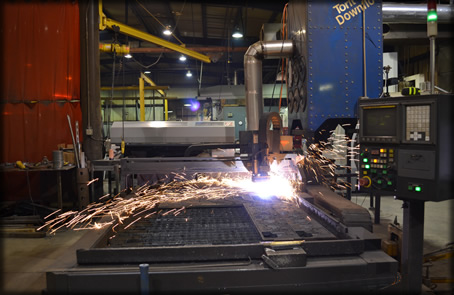

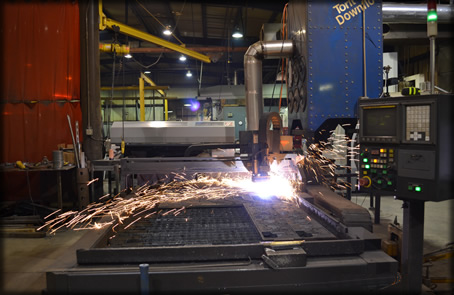

Waterjet Cutting Technology is a computerized cold-cutting technology that can cut most materials into any two-dimensional shape. Our system will precision cut materials such as carbon steel, stainless steel, aluminum, titanium, stone, glass and plastic up to six inches thick at a tolerance of plus or minus .005 or better. We can create parts, signs, art pieces, architectural applications; in fact, anything that can be drawn on a computer can be cut using our waterjet cutting system on the 6' x 12' table.Plasma Cutting

Our 150-watt Komatsu plasma cutter has a 5’x10’ table and is capable of cutting up to 1” thick carbon steel with minimal taper.